Promoting

and testing low Cost Housing Techniques: Latex Concrete Habitat

In January 2005, AIZON's founders undertook

a trip to the US to look at a low cost construction technology

developed in Colorado. As the techniques developed in the

US seem appropriate for Ethiopia and respond to the need for

low cost housing as well as for establishing a library, further

design work and field testing were conducted in Ethiopia.

The technologies best appropriate for low cost housing in

Ethiopia are a combination of latex concrete habitat and Adobe

construction.

1. Latex Concrete Habitat

Thin shell latex concrete roof have been

developed to answer low cost construction requirements in

poor regions where the need for cheap housing abounds (such

as in the southwestern region of the United States) or to

provide immediate shelter to displaced population groups .

Thin shell latex concrete surfaces are light weight, portable

and strong. These shells structures bear their loads in tension

and compression in their surface and hence do not need to

be heavy and thick. The light weight of the thin shells means

that they can be mounted on any combination of walls (conventional

bricks or HCB structures, Adobe blocks, wooden/iron poles,

etc...). This method also entails the lowest cost in materials

of any form of construction due to the fact that very little

material is actually used. The latex concrete shells are safe,

permanent, versatile and require little maintenance. They

can be constructed rapidly by unskilled labour.

The latex concrete techniques require Portland

cement, latex liquid and fiber glass fabric, all of which

are readily available in Ethiopia. The estimated cost of material

for thin shell concrete roofing in Ethiopia is below 40 Birr

($ 4.6) per square meter, which is the lowest of all construction

materials used in the country.

Albert Knott and George Nez,

“Latex Concrete Habitat”, Canada, 2005.

|

| Figure 1: Four

segments of latex concrete on existing wall (model) |

|

| Figure 2: Latex

concrete roof build in Afghanistan and placed on existing

mud walls for a school |

Albert Knott and George Nez, Ibid.,, 2005.

Albert Knott and George Nez, Ibid.,, 2005.

The figures above show a four segment of latex concrete on

an existing wall (model) and a latex concrete roof built in

Afghanistan and placed on existing mud walls for a school

(figure 2).

The construction of Yebelsa library in Bahar Dar/Ethiopia

will use the latex concrete technology for roofing and Adobe

blocks for walls or simple wooden columns for open reading

areas.

2. Adobe Construction

Adobe is one of the oldest building materials

in use. Adobe soil has clay and sand in such proportions that

when mixed into mud then dried out it forms a brick or a wall.

The best adobe soil will have between 15% and 30% clay in

it to bind the material together, with the rest being mostly

sand or larger aggregate. Too much clay will shrink and crack

excessively; too little will allow fragmentation. An adobe

brick is made of adobe soil and is sun cured on the ground.

Chopped straw or other fibers are usually added to adobe for

strength. Commonly adobe is shaped into uniform blocks that

can be stacked like bricks to form walls. A mold block developed

by Salam Children Village has been successfully tested by

AIZON P.L.C. in Bahar Dar. Adobe mortar is used to cement

adobe bricks together to create a wall. Some adobe buildings

have been plastered with Portland cement on the outside in

an attempt to protect the adobe, but this practice has led

to failures when moisture finds a way through a crack in the

cement and then can not readily evaporate. When adobe is used

as an exterior plaster it is stabilized. Portland cement can

be used for inside plastering.

In the past decade, Adobe construction techniques

have seen strong interest in the United States in particular

with the publication of numerous books on Adobe house construction

and actual residential construction in various cities. Compared

to HCB construction, Adobe provides better thermal regulation

and therefore more comfort in the building.

Adobe buildings that have substantial eaves

to protect the walls and foundations to keep the adobe off

the ground will require less maintenance than if the walls

are left unprotected. Adobe stands forever if it has a good

foundation, a good roof and has occupants who give it of periodic

maintenance. The oldest churches in Ethiopia demonstrate the

long lasting properties of Adobe.

3. Promotion of Adobe Block Construction

AIZON has lobbied the Municipality in Bahar

Dar to consider allowing the construction of Adobe house to

facilitate low cost housing for poor urban and sub-urban population.

Until recently, the Amhara regional government did not authorize

“Adobe/mud houses” construction within the boundaries of the

city. However, following a meeting held on the 19th of June

2005, the regional government has announced that Adobe house

will be permitted. AIZON provided technical guidance to the

relevant departments for the development of minimum standards

regulating mud house construction, using mud blocs.

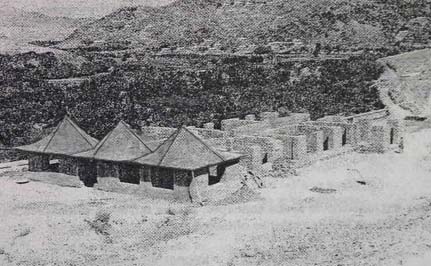

AIZON has successfully built a round tukkul

to be used as a store and field office at the arboretum site

using the Adobe block technique in Bahar Dar. The construction

has initiated interest amongst the poorer residents of Bahar

Dar.

|

|

View

of the round tukkul under construction, using Adobe

block (before plastering, May 2006)

|

|

| Outside

view of the tukkul under construction, using Adobe blocks

and traditional church design, May 2006. |

|

| Outside

view of the tukkul under construction, using Adobe blocks

and traditional church design, July 2006. |

|